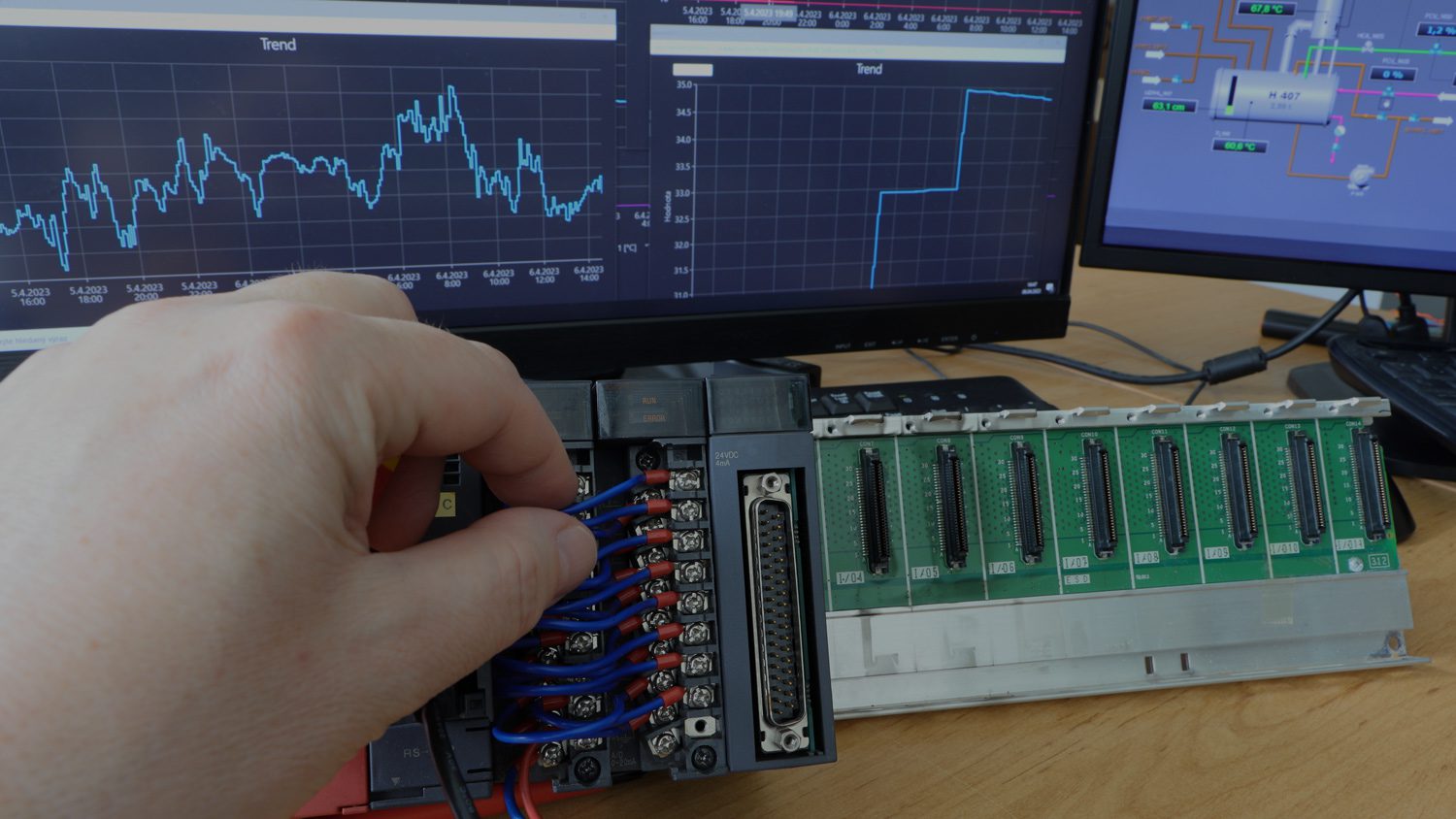

The client is a leading North American company specializing in Mechanical Contracting & Services. They have been serving the commercial, industrial, residential, and institutional markets for 50 years, providing essential services to ensure life safety and comfort. Their primary offerings comprise HVAC installation, HVAC service, maintenance, inspections, plumbing installation, and services. The project at hand required the development of FAB MEP Equipment Models, careful equipment selection, and coordination of Mechanical Services, Electrical Services, and PHE Services. One of the major challenges of this project was achieving accurate Spatial Coordination to ensure that all components of the system could function effectively without interfering with one another. Additionally, the scope of work included producing Shop drawings that met the project requirements and standards. However, this posed a significant challenge due to the need for a high level of accuracy and attention to detail, while ensuring that the drawings were completed within the given timeline. With TAAL Tech’s prompt ramp-up and execution methodology, the customer was able to accelerate construction activities. The output delivered by TAAL Tech was of high quality that it did not require any further modifications during the installation phase, saving time and costs. This exemplifies the value of efficient collaboration and technical expertise in achieving optimal project outcomes. The impact delivered was significant, with the hospital benefiting from a modern, efficient, and reliable MEP system that will support its operations for years to come. About Our Client

Business Challenges

Results Delivered

Want to learn more about this engagement?

Download the full case study