Top Trends in Plant Engineering for EPC Projects in 2025

Engineering, Procurement, and Construction (EPC) projects are rapidly evolving due to technological advancements, sustainability demands, and the need for efficiency. As we move into 2025, plant engineering is undergoing significant transformations driven by digitalization, automation, and eco-friendly innovations. This blog explores the top trends shaping plant engineering for EPC projects in 2025, providing insights into the future of industrial infrastructure development.

- Digital Twin Technology for Enhanced Project Management

Digital twin technology is revolutionizing plant engineering by creating virtual replicas of physical assets. These digital models help EPC companies predict performance, detect anomalies, and optimize operations. Key benefits include:

- Real-time monitoring and predictive maintenance

- Improved decision-making through data-driven insights

- Reduced downtime and operational costs

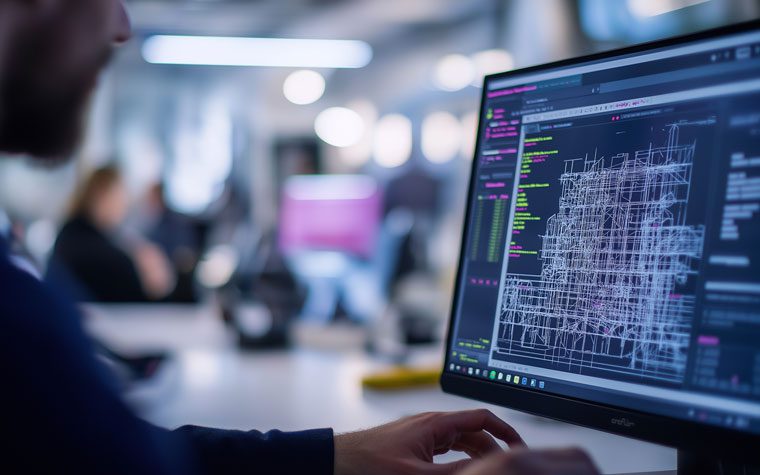

- Advanced Building Information Modeling (BIM) for Seamless Collaboration

BIM is playing a crucial role in EPC projects by facilitating multi-disciplinary coordination. In 2025, we expect increased adoption of 7D BIM, which integrates cost and sustainability factors. Advantages include:

- Improved clash detection and error minimization

- Enhanced design accuracy and efficiency

- Better lifecycle management of plants

- Artificial Intelligence (AI) and Machine Learning (ML) in Process Optimization

AI and ML are reshaping plant engineering by enabling:

- Predictive analytics for risk mitigation

- AI-driven automation for improved safety and efficiency

- Intelligent robotics for maintenance and inspections

AI-powered decision-making tools are becoming indispensable in optimizing workflows, ensuring cost-effective solutions for EPC firms.

- Sustainable and Green Engineering Practices

Sustainability is no longer optional for EPC projects. In 2025, plant engineering trends focus on:

- Use of renewable energy sources in plant operations

- Water and waste management solutions to minimize environmental impact

- Carbon capture and utilization (CCU) technologies to reduce emissions

Regulatory compliance and corporate social responsibility are pushing EPC companies to adopt eco-friendly construction and operational practices.

- Modular Construction and Prefabrication for Faster Project Execution

To address project delays and cost overruns, EPC companies are increasingly relying on modular construction and prefabrication. Key advantages include:

- Faster on-site assembly, reducing project timelines

- Lower material wastage and improved quality control

- Enhanced safety by minimizing on-site labor exposure

This trend is especially relevant in large-scale industrial plants and offshore installations.

- Industrial IoT (IIoT) for Smart Plant Operations

The Industrial Internet of Things (IIoT) is transforming plant engineering with connected devices that enhance monitoring and control. Benefits include:

- Real-time asset tracking and performance analytics

- Remote diagnostics for predictive maintenance

- Enhanced cybersecurity to protect critical infrastructure

IIoT integration ensures seamless communication across plant operations, leading to increased productivity and efficiency.

- 3D Printing for Rapid Prototyping and Customization

Additive manufacturing, or 3D printing, is revolutionizing EPC projects by enabling:

- Rapid prototyping of complex components

- Cost-effective customization of plant equipment

- On-demand production, reducing inventory costs

This technology allows EPC firms to experiment with innovative designs and accelerate production processes.

- Resilient Supply Chain Strategies

With global supply chain disruptions becoming a major concern, EPC companies are implementing:

- Diversified sourcing strategies to mitigate risks

- Blockchain technology for transparent procurement tracking

- AI-driven supply chain management for better forecasting

A robust supply chain is crucial to ensuring uninterrupted project execution and cost efficiency.

- Augmented Reality (AR) and Virtual Reality (VR) for Training and Maintenance

AR and VR are becoming essential tools in plant engineering for:

- Immersive training simulations for workers

- Remote troubleshooting and repair guidance

- Improved safety through hazard identification and response simulations

These technologies are enhancing workforce efficiency and reducing risks in complex plant environments.

- Decentralized Energy Solutions and Microgrids

As energy demands increase, decentralized power solutions are gaining traction in EPC projects. Trends in 2025 include:

- Integration of microgrids to enhance energy resilience

- Use of battery storage systems for uninterrupted operations

- Smart grid technologies for efficient energy distribution

These solutions contribute to sustainable and cost-effective energy management in industrial plants.

The landscape of plant engineering for EPC projects in 2025 is being shaped by cutting-edge technologies, sustainability initiatives, and efficiency-driven solutions. Digital twin technology, AI, IIoT, modular construction, and green engineering practices are redefining how EPC firms approach industrial plant development. Staying ahead of these trends will be crucial for engineering companies to optimize project execution, reduce costs, and maintain a competitive edge in the evolving industrial sector.

As plant engineering continues to advance, embracing these trends will be essential for EPC companies looking to drive innovation and sustainability in their projects.